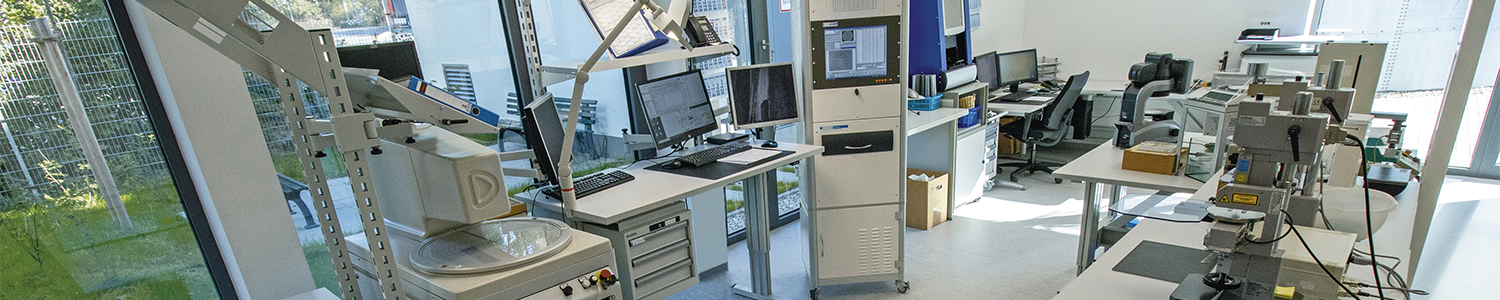

Dimensional inspections with the aid of the following measuring equipment:

▸ IM-6020 from Keyence (Fig. 1)

▸ Visio Kalix from UTP (Fig. 2)

▸ MIGG from DOSS

▸ AUTOGAUGE from Basler

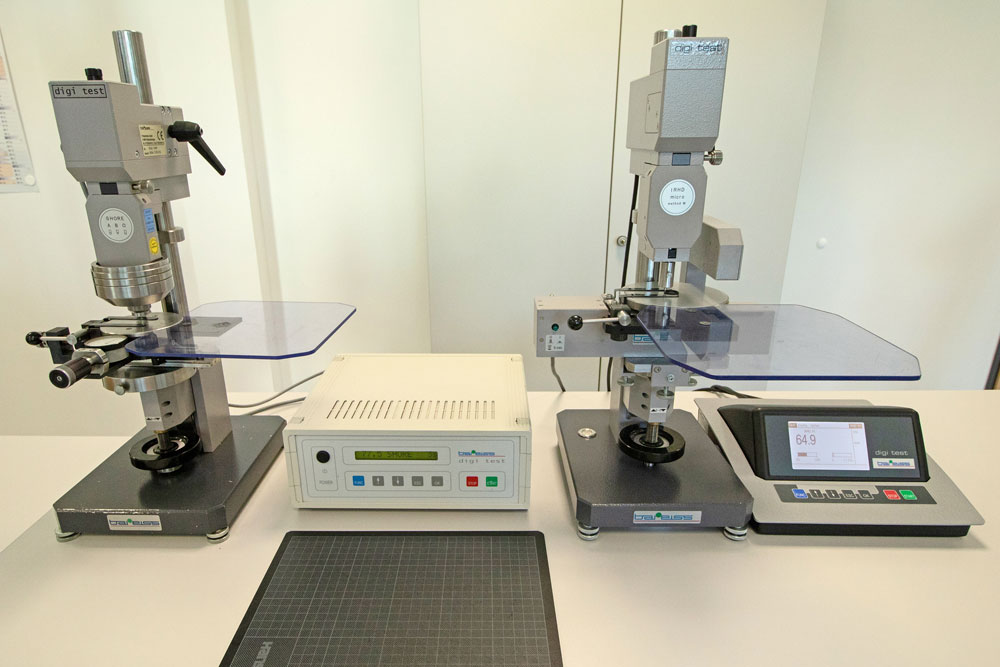

Hardness tests with the aid of the following measuring equipment:

▸ digi test II from Bareiss

For measurements in acc. with Shore A – DIN EN ISO 868 / DIN ISO 7619 / ASTM D 2240(Fig. 3)

▸ digi test II from Bareiss

For measurements in acc. with IRHD-M – DIN ISO 48 / ASTM D1415 (Fig. 3)

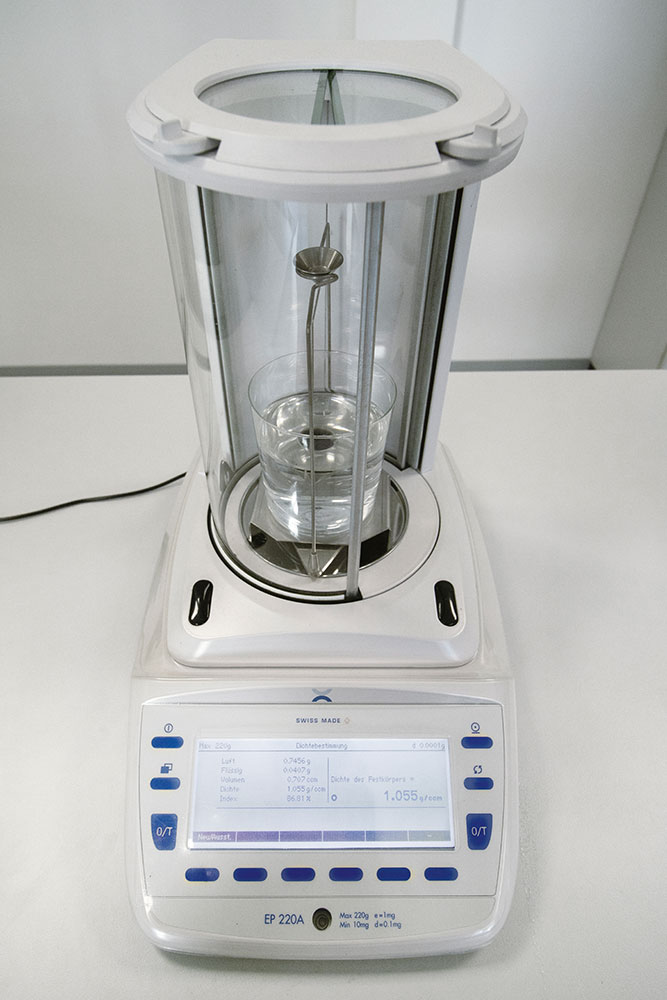

Leak-tightness tests with the aid of the following measuring equipment:

▸ PrecisaEP 220A (Series 360EP) in acc. with EN ISO 1183-1 (Fig. 4)

Visual inspections with the aid of:

▸ 2x magnifying glass

▸ Stereo microscopes

▸ Digital microscopes (Fig. 5)

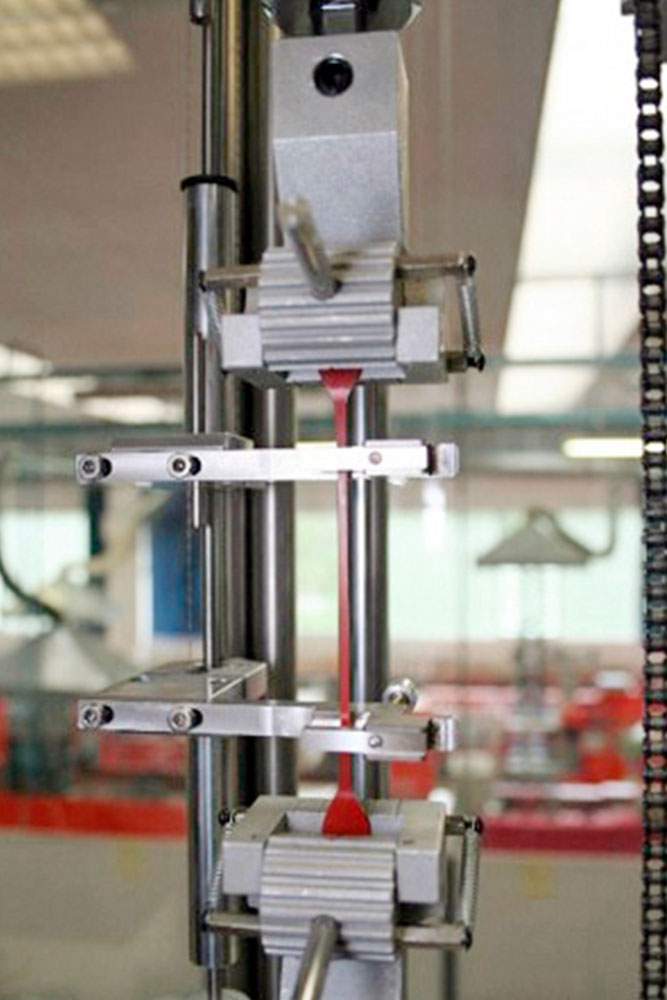

▸ Tensile tests in acc, with DIN 53504

Compression set inspections in acc. with DIN ISO 815, ASTM D 395 or customer specifications

Tensile tests with tensile testing equipment (Fig. 6)

Additional tests can be carried out in our manufacturing plant. Moreover, we have worked together for many years with renowned testing labs and compounders.

For more information, refer to our “Measuring procedures” section.