PTFE is a semi-crystalline polymer made of fluorine and carbon that is most well-known under the brand name Teflon® from DuPont.

For manufacturing purposes, PTFE in powder form is sintered to create semi-finished PTFE parts or finished PTFE parts.The incorporation of filler material (e.g. bronze, fiberglass, carbon/graphite) makes it possible to adapt the physical characteristics of the material to meet the specific application requirements. In general, the surface of PTFE exhibits a low friction coefficient along with a high level of resistance against aggressive chemicals and can be used in applications with a very wide temperature range.

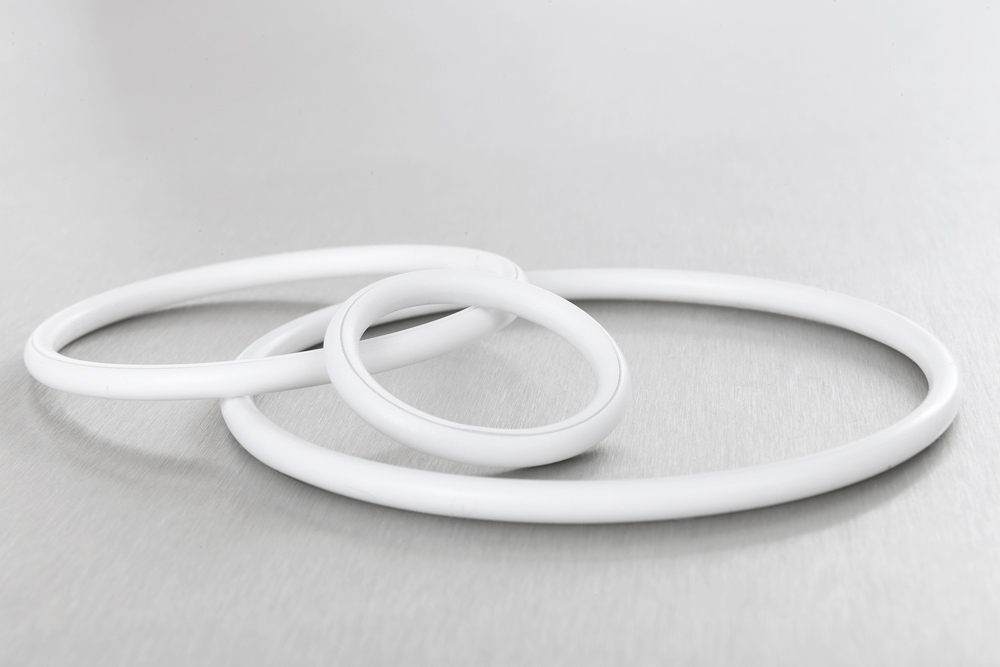

PTFE coating

Coating O-rings with PTFE. In this process, the elastomer core (generally FKM/VMQ/EPDM) is coated with one or more thin layers of PTFE. Position of impact and the number of layers (e.g. single/double coating) by arrangement. Application example: as a component in mechanical seals

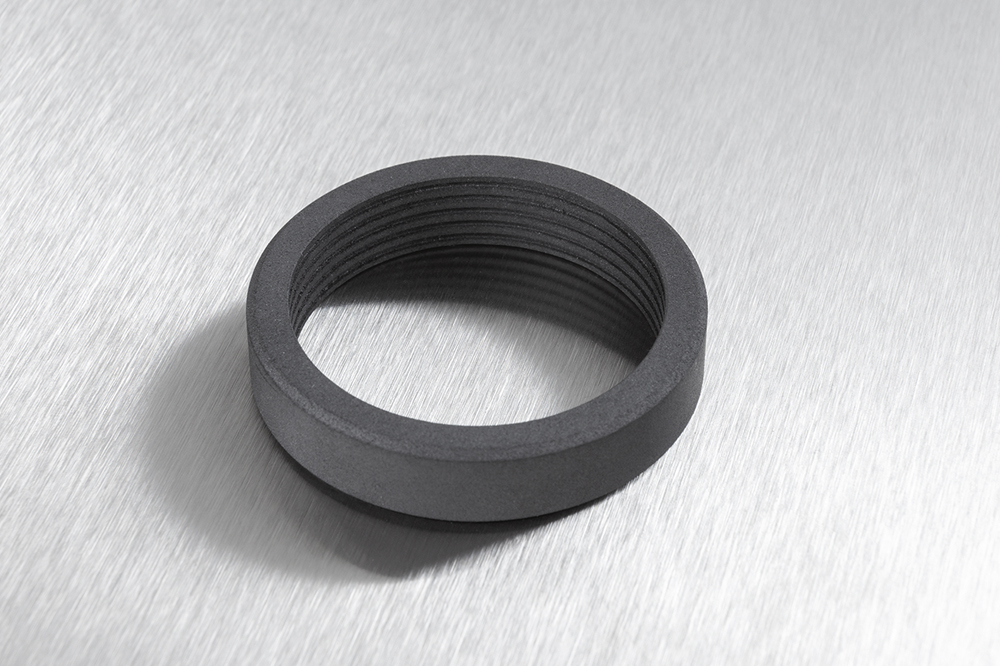

Turned parts made of PTFE

Machining production of customer-specific parts made of semi-finished PTFE products. Application example: support rings, O-rings

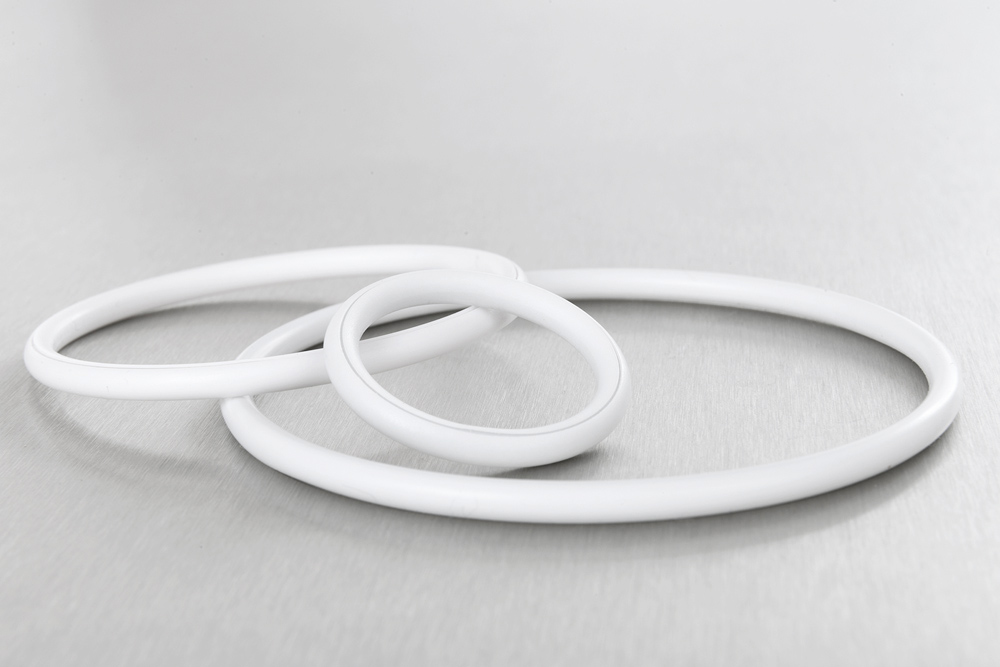

PTFE flat gaskets

Flat gaskets can be used to statically seal two sealing surfaces. Production is carried out based on the parts in question, e.g. using machining, sintering or punching semi-finished PTFE products.