Our wide range of measuring procedures allows us to guarantee not only the fundamental requirements for incoming goods inspections and formula conformity but also special, sometimes customer-specific quality requirements:

▸ Testing of physical material properties

▸ Testing of the material formula

▸ Additional tests

Testing of physical material properties

▸ Density measurement (e.g. in acc. with DIN ISO 1183-1)

▸ Hardness measurement (e.g. in acc. with Shore A – ISO 7619 Part 1 / in acc. with IRHDm–

ISO 48)

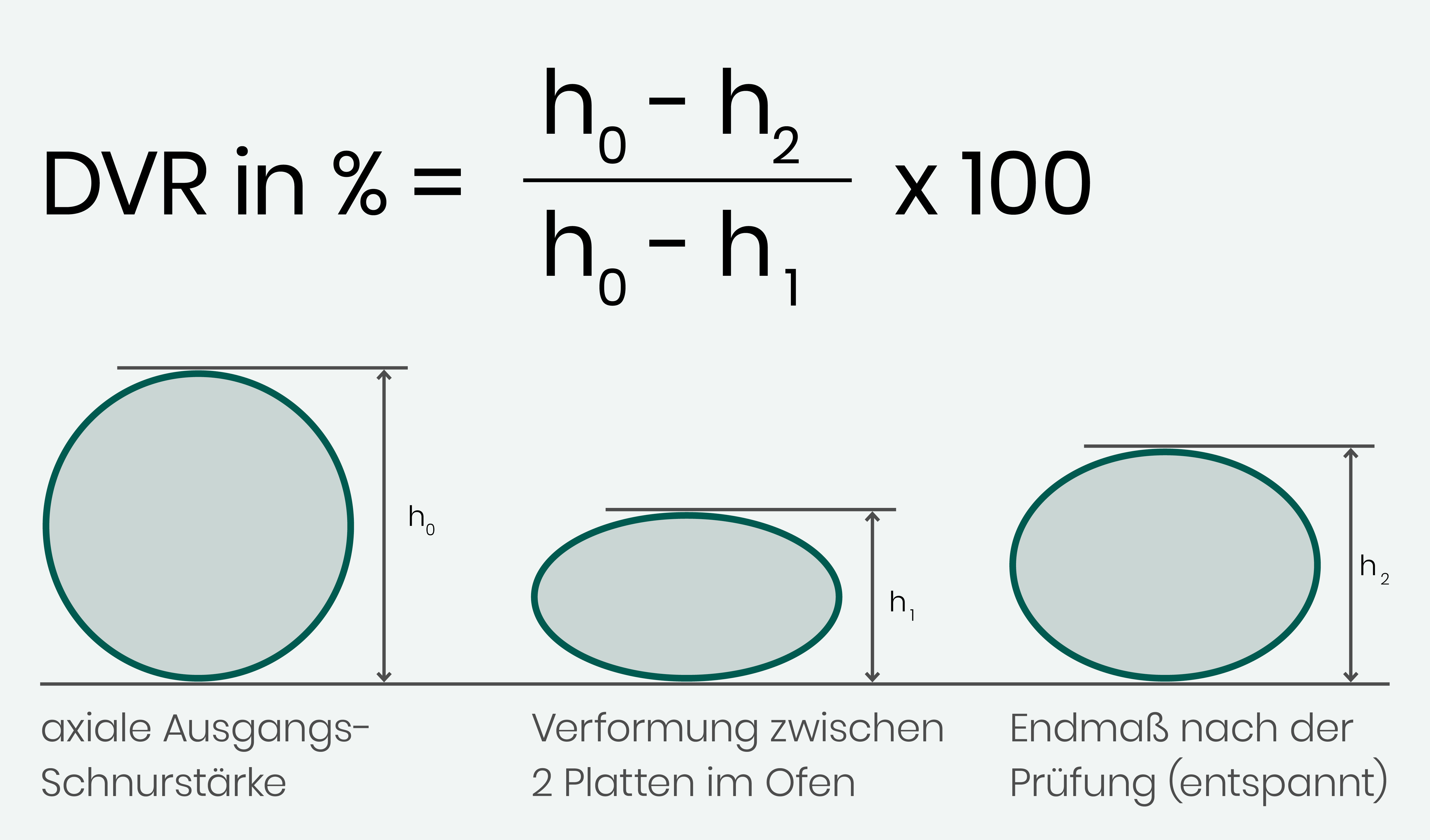

▸ Compression set (e.g. in acc. with DIN ISO 815)

The result provides us conclusions about the processing quality of the finished part as well as about the general material properties of the compound used.

▸ Rheometer

▸ Tensile testing (e.g. in acc. with DIN 53504)

▸ Tear strength (e.g. in acc. with ISO 34-1 or DIN 53507)

▸ Rebound resistance in acc. with DIN 53512 or ISO 4662

▸ TR10 test in acc. with ASTM D 1329 or ISO 2921

The TR10 value in acc. with ASTM D 1329 or ISO 2921 specifies the value in °C at which a specimen that was stretched 25% or 50% recovers by 10% after freezing. This value is the most informative cold temperature guide value for the assessment of sealing properties of O-rings or similar seals that constitutes a conservative low temperature limit. This means that, based on experience, even dynamically applied O-rings or O-rings that are exposed to pressure at low temperatures still seal until the TR10 value. For less stringent requirements, meaning static sealing against ambient pressure, O-rings can still seal until approx.10–15°C below the TR10 value according to experience.

▸ Thermomechanical analysis – TMA

▸ Dynamic mechanical analysis – DMA

▸ Ozone resistance testing in acc. with DIN 53 509 or ISO 1431

▸ Measurement of the electrical properties of elastomers

Testing of the material formula

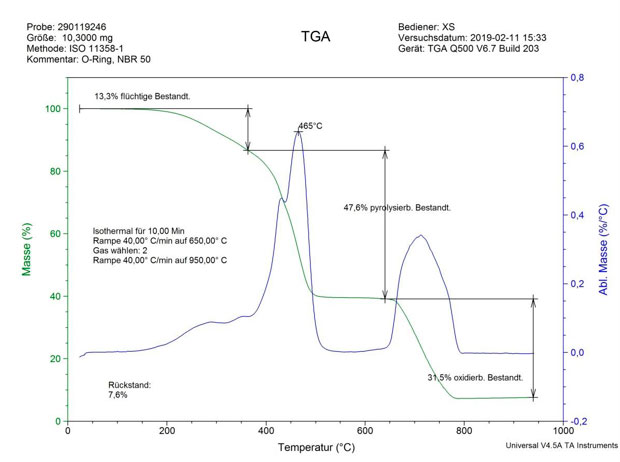

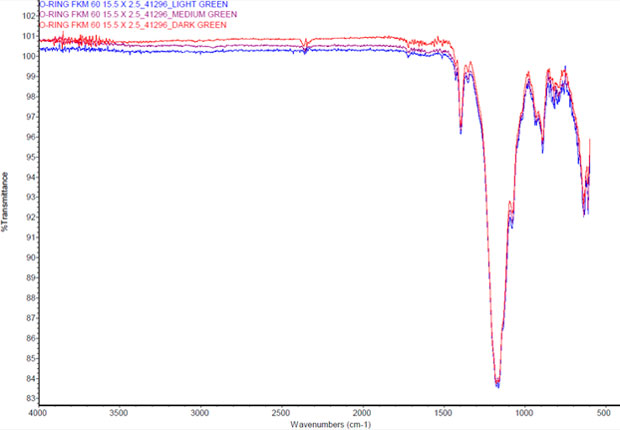

Fourier-transform infrared spectroscopy – FTIR

The results of an infrared spectroscopy make it possible to identify the individual ingredients in the elastomer formula (chemical composition).

Differential scanning calorimetry – DSC

The results of a DSC test can determine the low-temperature range or the temperature limits.

Additional tests

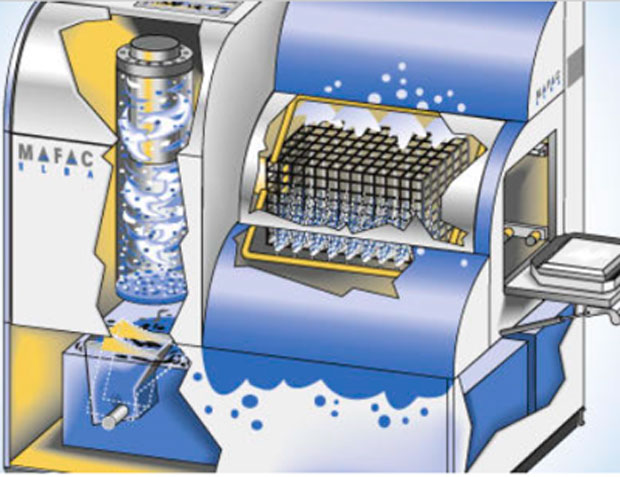

Testing of the defined cleanliness requirements in acc. with ISO 16232, VDA 19, etc.

Exemplary procedures:

▸ Acceptance of any impurity of the components

▸ Quantitative determination of the degree of impurity

▸ Qualitative determination of the impurity (particle type, quantity, size)

Testing of the sliding properties of components:

e.g. by determining the sliding friction coefficient (friction test)

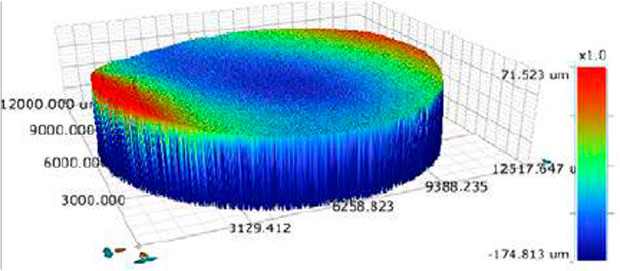

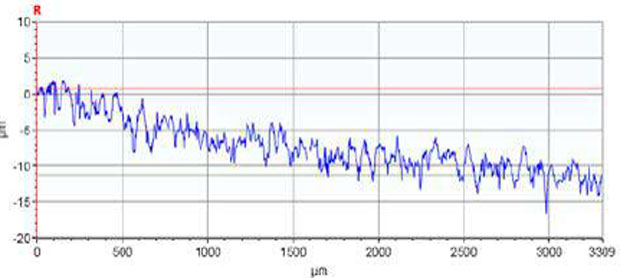

Testing of the surface roughness:

Due to the properties of elastomers, standard testing procedures (e.g. tactile procedures) cannot be used. As a result, optical measuring procedures must be used instead.