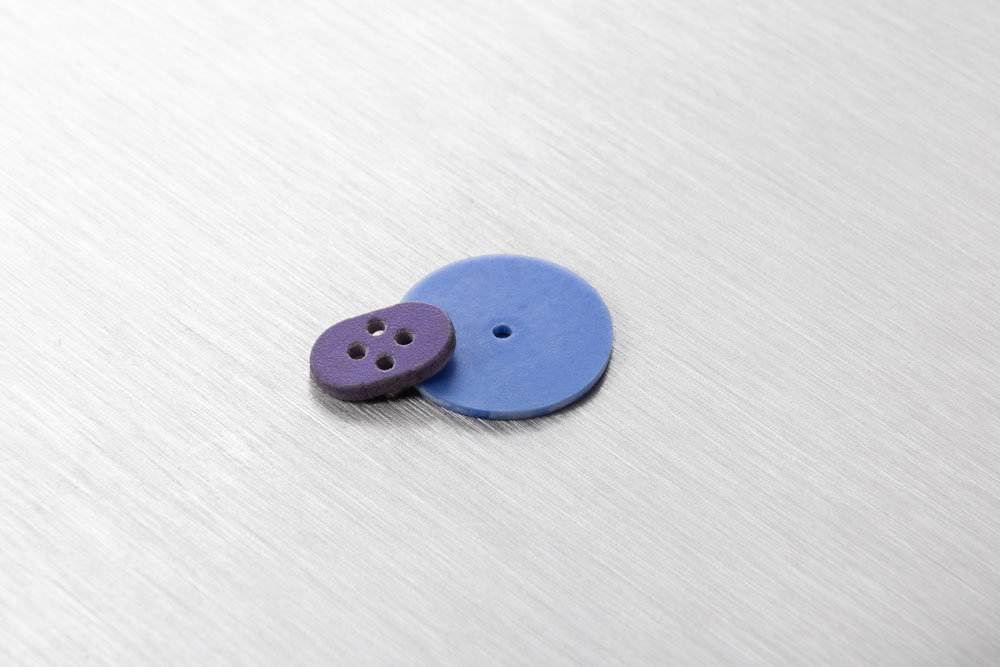

Flat gaskets are made of calendered or compression-molded sheet material and are characterized by two plane-parallel surfaces with different contours.

Radial-symmetrical flat gaskets are the simplest version. Possible manufacturing processes are water jet, plotter and laser cutting or punching. Flat gaskets can also be cut from a hose (hose ring).

Water-jet cutting

Using water-jet cutting to manufacture flat gaskets from calendered or compression-molded sheet material. This technology requires no additional tools. The cut edge is rectangular. All common elastomers can be used as the sheet material, as can, for example, all foam, cork or cellular rubbers. If required, self-adhesive film may be applied to the carrier material to simplify assembly.

Punching

Using punching to manufacture flat gaskets from calendered or compression-molded sheet material. This technology requires a special tool. All common elastomers can be used as the sheet material, as can, for example, all foam, cork or cellular rubbers. If required, self-adhesive film may be applied to the carrier material to simplify assembly.

Plotter cutting

Using plotter cutting to manufacture flat gaskets from calendered or compression-molded sheet material. This technology is suitable for the economic manufacturing of small batches because no tools are required. All common elastomers can be used as the sheet material, as can, for example, all foam, cork or cellular rubbers. If required, self-adhesive film may be applied to the carrier material to simplify assembly.

Laser cutting

Using a laser to manufacture flat gaskets from calendered or compression-molded sheet material. The material and geometry determine whether this technology can be used.

Hose/square rings

Hose rings are made of compression-molded hose pieces and cut on the basis of height. This process results in a compression-smoothed internal and external surface and an extremely sharp-edged design with narrow tolerances.<br />