Molded parts are customer-specific elastomer parts that are created on the basis of drawings and manufactured in close coordination with the customer in accordance with the individual installation conditions and application in question.

The production – using all standard elastomers as well as thermoplastics – is carried out on a part-specific basis using either compression, injection or transfer molding. The production quantity is determined in conjunction with the customer based on their needs – pilot, small-batch and serial components are possible. Prototyping is done using a pilot component or 3D printing.

The following overview contains a list of just some of the many molded parts we offer.

Membranes

Area of application: dosing, regulating and control devices. Because a variety of factors including rebound force, lift height, damping and pressure differentials must be considered, a detailed technical evaluation and coordination with the customer is required. Material: Elastomers, fiber-reinforced elastomers.

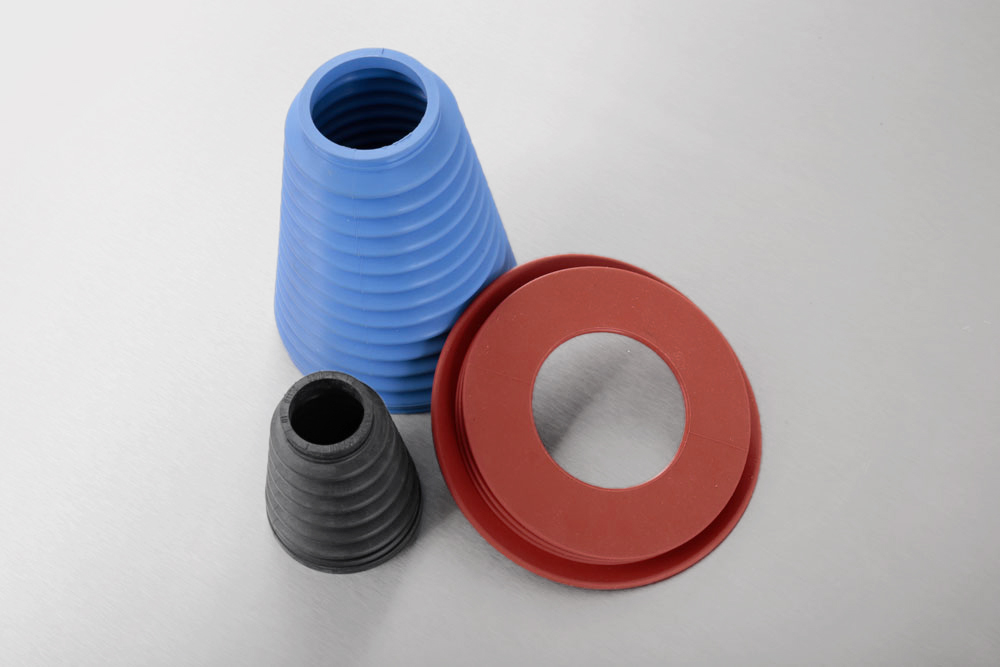

Cable bushing

For sealing feed-throughs or ducts (e.g. walls, pipes). Depending on the seal design, individual, slightly perforated plugs can be removed to allow for maximum flexibility.

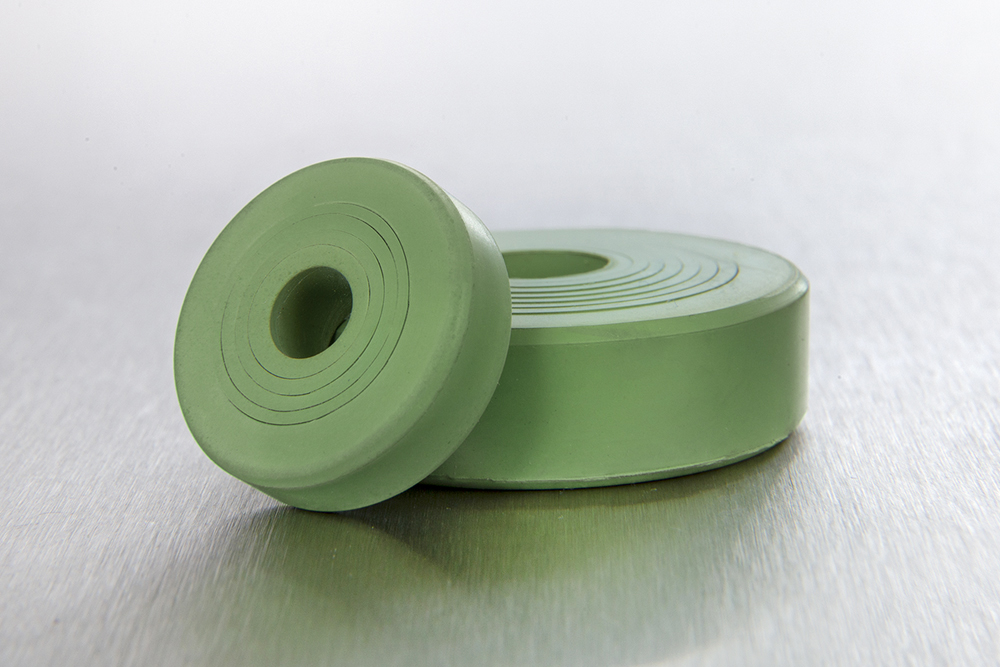

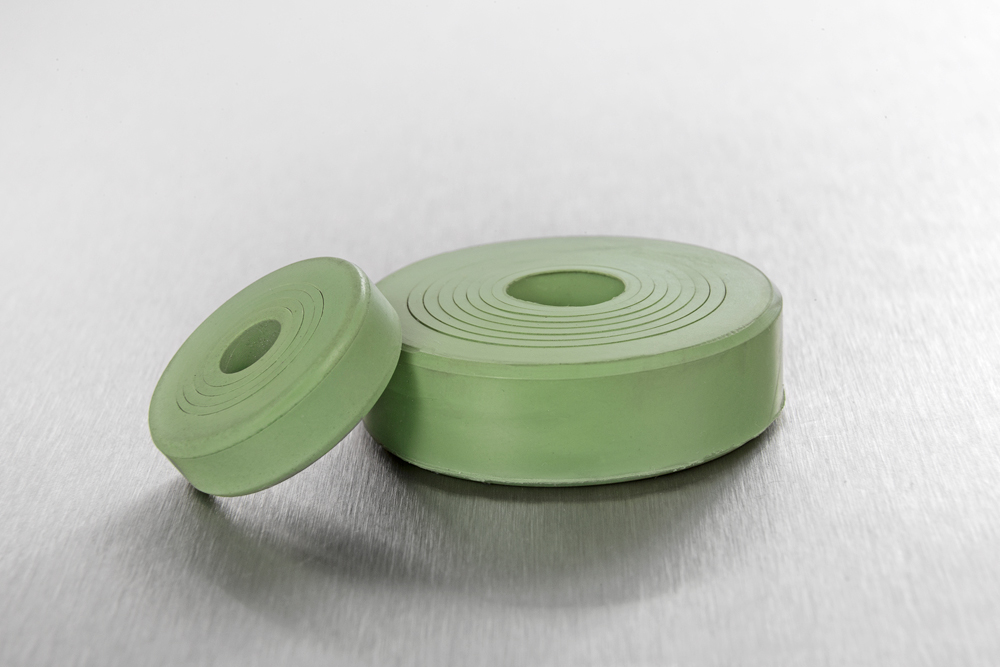

Tapered ring seal

A special cutting procedure is used to cut concentric, tapered rings into the base of the seal. Individual rings can be removed as needed, which makes it possible to effectively seal a wide range of cable diameters.

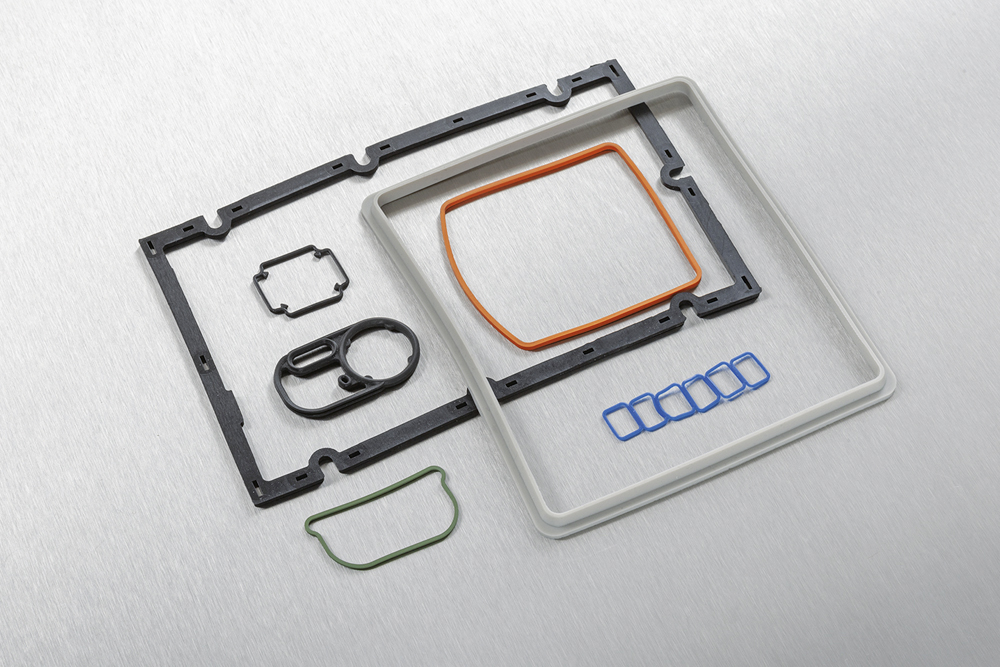

Frame seal

Often used to seal housing components and valve covers in an extremely wide range of application scenarios.

Folding bellows

Folding bellows are an extremely flexible sealing element that are used in joint and piston seals. The number and thickness of the folds are combined in a sophisticated design. Proprietary manufacturing technology is required.