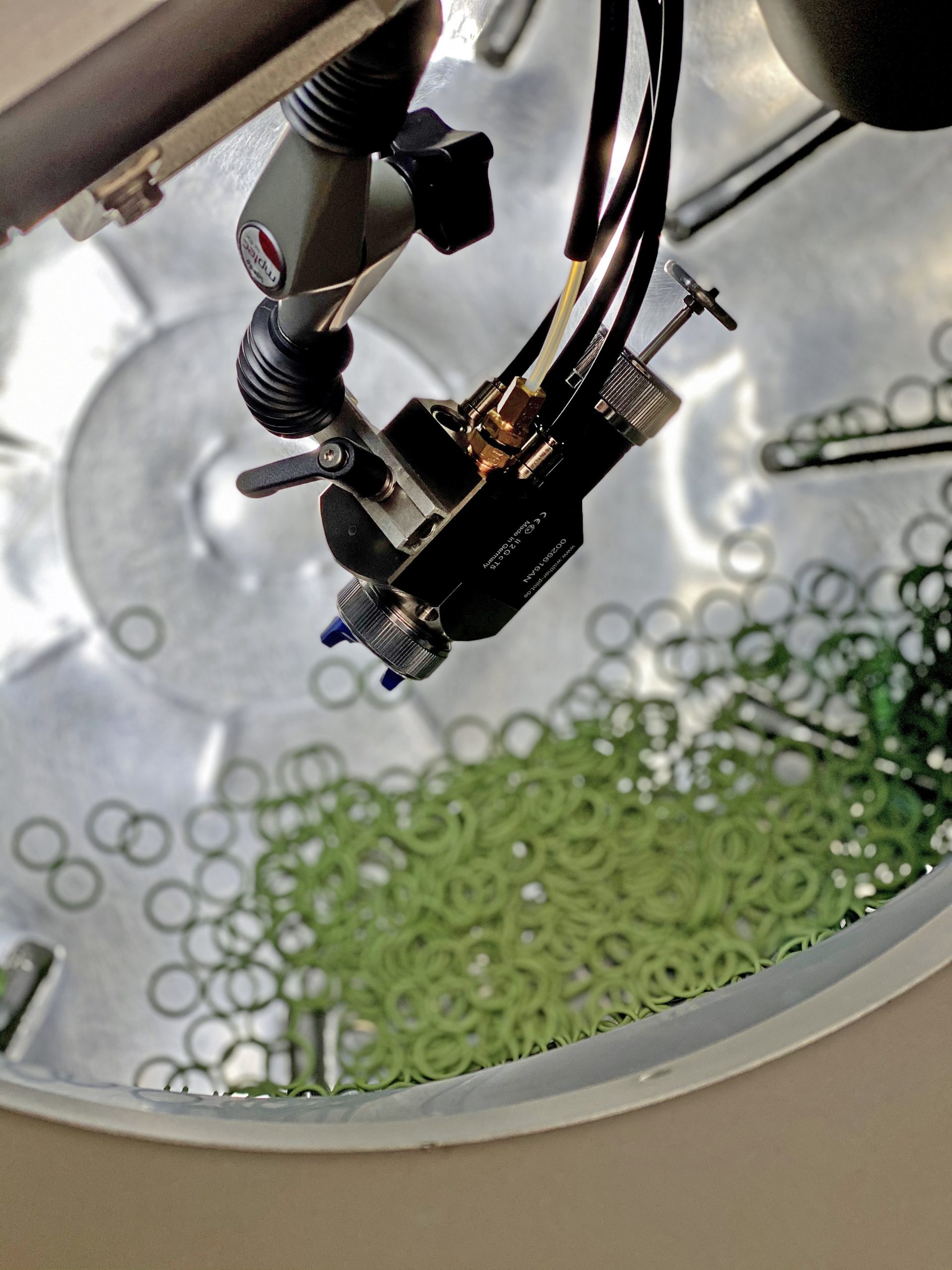

Seals can be coated with transparent or colored, elastic, environmentally-friendly bonded coatings made either on a water or solvent basis. For example, we can apply PTFE-based bonded coatings that are applied in a variety of ways: spray drum, dipping, hand coating, plasma treatment, …

Possible areas of application are wherever it is necessary to differentiate between components (e.g. similar O-ring dimensions), to change color without affecting the material properties (e.g. a black material), or the design (color consistency across multiple batches, color choice acc. to specifications)

Moreover, coatings are often applied for functional reasons: reducing friction, simplifying assembly, non-stick properties, altering the electrical surface resistance, noise reduction, reducing wear in dynamic applications, …

Additional surface treatments:

Moly coating

Seals can be treated with MoS2 powder. This can, for example, keep components from sticking to one another and significantly improve gliding properties. The coating is applied using a drum.

Talcum powder coating

Seals can be treated with talcum powder. This can, for example, keep components from sticking to one another. This procedure is also very cost-effective. The coating is applied using a drum.

Silicon coating

Seals can be treated with a transparent silicon emulsion. This significantly improves the gliding properties while keeping costs low. The coating is applied using a drum.

Graphite coating

Seals can be treated with graphite powder. This can, for example, keep components from sticking to one another and significantly improve gliding properties. The coating is applied using a drum.

Labels

Labeling components in order to

▸ differentiate between materials with the same color or between similarly sized components

▸ ensure proper installation and assembly

Labeling options:

▸ A colored dot on the surface (positioning, color, number of dots based on customer specifications)

▸ Colored coating (See also bullet point/Add link to: Surface treatments)

Cleaning

Various procedures can be used to clean elastomer components in order to perform tasks such as remove any non-vulcanized materials, oils, greases, silicones, production aids or dirt.

Surface cleaning options:

▸ High-pressure cleaning with a special cleaning system

▸ Plasma treatment

▸ Ultrasonic bath

Purpose of surface cleaning:

▸ Meet cleanliness requirements based on customer specifications

▸ Perform cleanliness analyses in acc. with common industry guidelines (e.g. ISO 16364 or VDA 19)

▸ Remove any substances that are detrimental to paint adhesion

▸ Ensure components are free of silicone